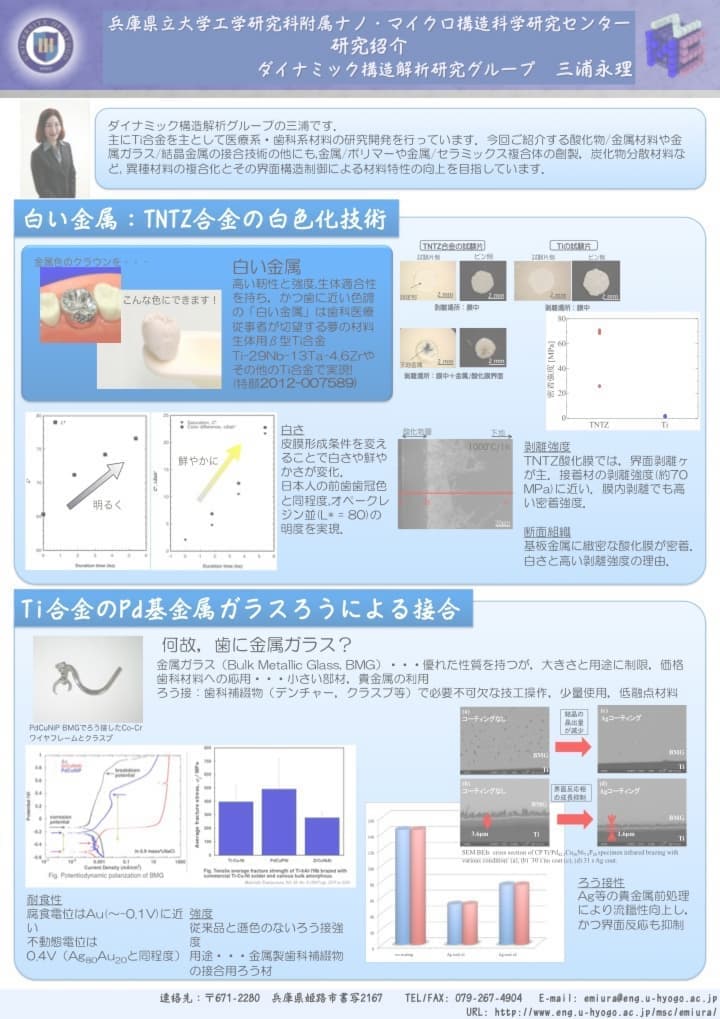

"The white metallic" which is an long awaited material for the dental industry. It is a metaphor of the material which has the strength and toughness like a metal, and has whiteness like a tooth. Our group fabricate the “white metal” by means of oxide film coating method. We are investigating with respect to its aesthetic property (color tone), the evaluation of peeling resistance, the formation mechanism of the oxidized film, etc.

耐食性と強度に優れた金属ガラス(bulk metallic glass, BMG)ろうの生体用金属材料の接合への応用を目指し,主に貴金属系のBMGのろう接性について調べています.現在,ろうのぬれ性の向上のため,基板へコーティング材とぬれ性の関係について調べています.

Aiming at the application to a corrosion resistivity and a junction of the biocompatible metal of the metallic-glass (bulkmetallicglass, BMG) brazing filler metal excellent in the strength, I am mainly investigating about the brazing-and-soldering nature of BMG of a precious-metals system. Now, I am investigating about the relationship between a coating material and a wettability to the substrate for the improvement in the wettability of a brazing filler metal.

人工関節や歯科インプラントなど,生体組織や他の部材と常に接触があり,常に稼働する部位において,摩擦摩耗は重要な機械的性質です.生体用金属材料の生体内での微少摺動環境を想定した摩擦摩耗挙動を知り,X線回折法や組織観察でどのような表面損傷が起こるかを調べています.

In the part which an artificial joint, dentistry implant, etc. always have contact with a living body tissue and other members, and always works, frictional wear is an important mechanical property. I get to know the frictional wear behavior supposing the very small 摺動 environment of a biocompatible metal in the living body, and am investigating what kind of surface damage happens by a X-ray diffraction method or tissue observation.

インプラントや骨プレートなど,骨折部の補強や欠損の補綴に使われる生体材料用金属材料Tiは,骨より高いヤング率を持つ事による応力遮蔽に起因する骨吸収等が問題になっています.「最初はヤング率も強度も高く,骨とくっついたら骨並みになる」材料を作る!を目標に,TiとPMMAやリン酸カルシウムなどの生分解性材料の複合材を粉末冶金法で作製し,その機械的性質について調べています.

biomechanical materials used for a reinforcement of a fracture division, or prosthetic dentistry of a fracture, such as implant and a bone plate, -- public funds -- the bone resorption resulting from the stress shielding by genus material Ti having a Young's modulus higher than a bone, etc. have been problems. I make the material "which will become just like a bone if a Young's modulus and the strength of an initial are high and it adheres with a bone"! For the purpose of an it1, I produce the composite materials of biodegradable materials, such as Ti, PMMA, and calcium phosphate, with a powder metallurgy process, and am investigating about the mechanical property at it.

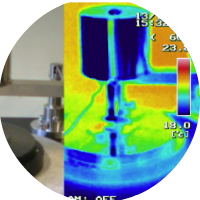

自動車や航空機産業分野では,溶接の難しいAlやステンレス,Ti製部品の接合方法として,摩擦攪拌接合(friction stair welding, FSW)が実用化されています.Ni基超合金を凌駕する次世代の超耐熱Mo-Si-B合金のステンレスやTi合金など高融点材料用FSW 用ツールチップ材としての応用の可能性を探るため,耐摩耗性の評価を行っています.

In the vehicle or the aviation field, friction-stir welding (frictionstairwelding, FSW) is put in practical use as the junction manner of difficult aluminum and stainless steel of a spot-welds, and the componentses made from Ti. In order to explore the application possibility as a tooltip wood for FSW for high melting-point materials, such as next-generation stainless steel of a super-heat-resistant Mo-Si-B composition metal, Ti composition metal, etc. which exceed nickel basis superalloy, I am performing the wear-resistant evaluation.

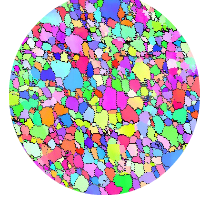

粉末冶金によって作製したTiC微細分散SUS316L材は,TiC粒の粒界ピン止め効果によるオーステナイト粒の結晶成長抑制効果が表れます.TiC分散の機構を探ると共に,結晶粒径と耐摩耗性の関係を調査しています.

The grain-growth depression effect of the austenite grain according [ the TiC fine dispersion SUS316L wood produced by the powder metallurgy ] to the region-near-grain-boundaries bobby pin effect of a TiC grain appears. While exploring the organization of a TiC variance, I am investigating the diameter of a crystal grain, and the wear-resistant relationship.

前のページへ

前のページへ